By Gail Dutton

Cell lines represent a particularly tight bottleneck in biomanufacturing. Conventional cell lines—such as those used in CHO, bacterial, and baculovirus–insect cell expression systems—reveal their limitations when supplies of vaccines and biologics fall short of demand. An obvious example: shortages of COVID-19 vaccines. Less remarked upon, but still worrying, are shortages of monoclonal antibodies and other biologics.

Because conventional cell lines are already highly optimized, large gains in their productivity are unlikely. Moreover, these cell lines pose inherent challenges. For example, expression systems based on these cell lines are subject to contamination with endotoxins and viruses. Removing these contaminants increases costs and delays product releases.

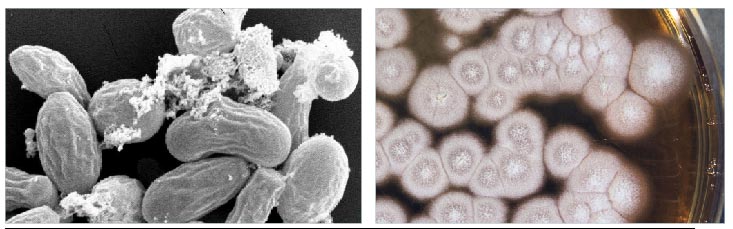

Some of the downsides encountered with conventional expression systems can be avoided with cell culture platforms based on filamentous fungi. An example of a fungal platform is the C1 platform, which has been developed by Dyadic International. The C1 platform is based on Thermothelomyces heterothallica, a filamentous fungus that is generally recognized as safe (GRAS) by the U.S. Food and Drug Administration. At present, the C1 platform in Phase I trials is being used to produce a COVID-19 booster vaccine.

An enlightened approach

“There’s a huge gap in the technologies the biopharmaceutical industry uses versus what’s used in industrial biotechnology,” says Mark Emalfarb, CEO, Dyadic. According to Emalfarb, the gap reflects the biopharmaceutical industry’s aversion to risk and resistance to change. The industry, he complains, is “stuck in the Middle Ages.” His advice is that the industry should shift its focus from incremental improvements to a complete rethink of cell culture models.

“Very few filamentous fungal platforms exist,” Emalfarb notes. “They’ve been very expensive to create, and they’ve been difficult to use at large scale. Filamentous fungi are typically very viscous.”

To address the viscosity issue, the Dyadic team used a morphological mutant of T. heterothallica as the basis of the C1 platform. At the end of the fermentation process, the organism grows at something like 10 centipoise. This is reasonably low, given that the viscosity of water at 20°C is about 1 centipoise.

“It also grows under human physiological conditions—ideally at 6.7 pH and 37°C—but it can grow at pH 5 to 8, and at temperatures from 20° to 45°C,” Emalfarb reports. These ranges, he adds, show that the C1 platform is robust and versatile.

Advantages of the C1 platform

“We took a protein that was not purified—about 95% was background, and 5% was of interest—and injected it into mice for the GRAS toxicology/pathogenicity studies, and it was found to be safe,” Emalfarb says. Consequently, when just the portion of interest is used, “you have no endotoxins (like you have with Escherichia coli expression systems) and no viruses (like you have with CHO or baculovirus–insect expression systems), so the pedigree is probably safer.”

He also says that the C1 cell production platform is faster and more productive than more traditional systems. This enables one 2,000-L bioreactor to do the work of a 15,000-L bioreactor. The system can scale from 1 L to 500,000 L in stainless-steel or single-use stirred tank fermenters.

For example, when the C1 platform was used to produce nivolumab, the seven-day yield was 22.5 g/L—a significant increase from the benchmark of 2.5 g/L using inexpensive, chemically defined synthetic media. In contrast, CHO cells typically produce 4–10 g/L in 14 days. “The C1 platform,” Emalfarb asserts, “can handle complex proteins that certain other cells may not be able to express in yields that are sufficient to commercialize.”

Fermentation is also faster. “From the point a stable cell line is taken from the freezer to the end of fermentation is 12–14 days for the C1 platform, and 41–52 days for CHO cells,” he says. “So, we can run three or four batches in the time it takes to run one batch with CHO cells.”

External projects confirm C1’s high productivity and speed. “In the European Zoonosis Anticipation and Preparedness Initiative, it was demonstrated that our C1 cell production platform was 300 times more efficient than baculovirus,” Emalfarb relates. The time to release was further reduced by up to a month by not having to remove viruses from the culture. At the National Institute for Innovation in Manufacturing Biopharmaceuticals, C1 outperformed alternative platforms in terms of speed, yield, and cost when producing antibody fragments and monoclonal antibodies.

A filamentous first

Dyadic’s fungal platform is being used to produce a COVID-19 booster vaccine (DYAI 100) currently undergoing clinical trials in South Africa. “This is a protein antigen produced from the C1 cell line,” Emalfarb says. “As far as I know, it’s the first time a protein produced by filamentous fungi has been injected into humans in a Phase I trial.” When dosing was completed, Dyadic reported that there had been no serious adverse events. Emalfarb expects that the trial will show favorable antibody responses. Eventually, the booster vaccine may be out-licensed.

In work with Janssen, Dyadic is using the C1 platform to produce some of that company’s product candidates. Dyadic has also collaborated with multiple research institutes to express antigens and antibodies to help combat emerging diseases.

“We’ve worked on West Nile virus; H1, H5 (avian flu), and H7 strains of influenza; and other viral infections,” Emalfarb points out. “We’re not a one-trick pony.” He adds that Dyadic can also make the full spike protein as well as the receptor binding domain fragments of SARS-CoV-2.

In addition to vaccines, the C1 platform can produce monoclonal antibodies and other therapeutic proteins. “In some ways, I think that is an even bigger point than vaccines,” Emalfarb declares. He is eager for the advantages of the C1 platform to become more widely known. He says, “I think that in many cases, the C-level people are unaware of the difference between what they have and what they could have in terms of speed, cost, and productivity.”

An unusual origin story

Emalfarb formed Dyadic in 1979 to supply Icelandic pumice for stone-washed jeans. When enzyme washes became more cost-effective and environmentally friendly, he changed with the times, selling enzymes made by major manufacturers and, eventually, making his own.

“When the Berlin Wall fell, the U.S. government wanted peaceful outlets for Russian scientists,” he recalls. “We hired 35 Russian scientists to find organisms we could use to make enzymes to wash blue jeans. A few years later, we developed C1 technology.” The C1 platform has allowed Dyadic to reduce the cost of manufacturing enzymes from $18 per pound to approximately $1 per pound.

“We manufactured and sold enzymes in 35 countries,” Emalfarb says. He licensed the technology to Abengoa, Shell Oil, and Codexis for biofuels, and to BASF for industrial enzymes. After selling the industrial side of the business to DuPont in 2015, Dyadic started using the hyperproductive C1 platform for biopharmaceutical applications.

Immediate focus

Dyadic sees opportunities to develop products in-house, to out-license its technology, and to provide contract manufacturing services. The company’s immediate focus is on using the Phase I trial in South Africa to demonstrate the safety of proteins produced with the C1 platform. That trial is generating interest in the C1 platform and advancing Dyadic’s quest to improve cell culture productivity and, ultimately, human health. “It’s nice to make profits,” Emalfarb says, “but at some point, as responsible human beings, we also need to provide health equity to a global population.”