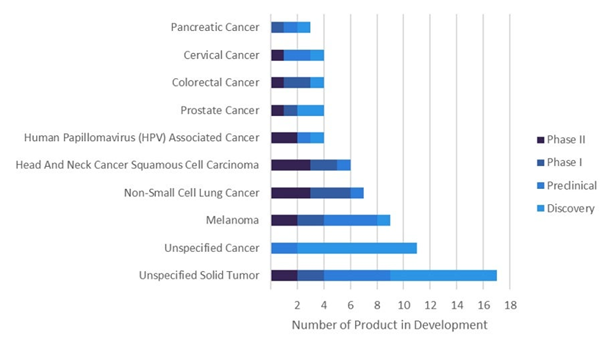

It isn’t often that pharmaceutical advancements break out of laboratories to become household names. Messenger RNA (mRNA) treatment, however, has managed it. A cornerstone of the global response to the Covid-19 pandemic – mRNA vaccines represent six out of 13 approved Covid-19 vaccines and boosters in the seven major pharmaceutical markets of the US, France, Germany, Italy, Spain, the UK, and Japan – its potential is obvious, and yet to be fully exploited. Treatments based on mRNA could soon provide answers to intractable medical problems; according to GlobalData, the worldwide market for mRNA-based oncology therapies could be worth over $2 billion by 2028. Dozens of anti-cancer treatments using the technology are currently in development.

In a globalised world, infectious disease is an irrepressible opponent. Meanwhile, new frontiers of biopharmaceuticals – like gene editing and personalised medicine – are opening all the time. Industry leaders recognize that mRNA treatments could hold the key to all this and more. And biomanufacturers must pay heed to the relentless advances that are helping to make a once-elusive therapy more efficient and accessible than ever before.

Diverse applications, big potential

At the heart of mRNA technology is its central role in biology. Serving as the messenger between DNA’s permanent genetic code and the dynamic proteins within cells, mRNA plays a pivotal role in the translation of genetic information into functional proteins. This understanding forms the foundation for mRNA use in medicine.

To design mRNA as an effective molecule for its intended application, biomanufacturers need to amend processes to maximise its likelihood of success. Ben Hudson, Associate Director of Biology R&D at TriLink BioTechnologies®, points out that mRNA’s principal benefit is that its components can be modified depending on desired use. He gives the example of a vaccine: “In that setting, you would prioritise robust protein production and a strong – but not too strong — immune response. So, you’d want a design that puts an emphasis on the longevity of the RNA, including a cap structure, poly(A) tail length and UTRs that have been optimised for your use case, and for your antigen or your protein to deliver the longest expression and the most robust response.”

New research avenues in gene editing, however, might require mRNA to be engineered in a different way altogether. “You might require two RNAs,” says Hudson. “One might be designed to produce a Cas9 protein that is destined for the nucleus. The goal for this mRNA would be a high protein production type of RNA with a cap, UTRs, modified bases, and poly(A) tail that are designed to drive protein production. And then you would have a separate RNA, the guide RNA, that would have no caps or poly(A) tail but might have specifically-modified bases to promote stability.”

Understanding the intricate mRNA manufacturing process is crucial for sidestepping the pain points. It begins with a DNA template for in vitro transcription. A critical aspect of mRNA manufacturing is the delivery system. lipid nanoparticles (LNPs) have emerged as the preferred delivery mechanism, ensuring both mRNA stability within the LNPs and efficient cellular uptake. Jordana Henderson, Associate Director of Technical Design at TriLink, notes that other delivery mechanisms are currently being explored. “Alternatives include polymer nanoparticles, peptide-based complexes and even exosomes,” she says. “The role of each delivery vehicle is the same: it should facilitate uptake of the RNA into appropriate cells and serve to protect mRNA from degradation until it is released into the cytoplasm for translation.”

Modified nucleobases in mRNA have garnered attention due to their role in evading the innate immune response. Exogenous mRNA can often stimulate innate immune mechanisms, making the use of modified bases essential. N1-methylpseudouridine is one such modification, allowing mRNA to sidestep the overstimulation of the innate immune response.

Avoiding the cap trap

One of the most vital parts of any mRNA manufacturing procedure is generation of the 5′ cap. The 5′ cap is essential for mRNA functionality but cannot be templated by the DNA; its functions include stabilizing mRNA and enabling mRNA to undergo translation for protein synthesis, ensuring desired immune responses to the coded antigens in the case of vaccines. The challenge for biomanufacturers is to utilize synthetic caps that are up to the job.

Novel technologies are helping to push boundaries in this area. CleanCap® technology, for instance, is advancing understanding of what was previously thought possible in the realm of synthetic cap manufacturing – enabling production of mRNA with Cap 1 structures with over 95% efficiency. The CleanCap® technology utilises co-transcriptional capping – where cap analogs are added directly to the in vitro transcription’s reaction mix and incorporated into mRNA’s 5′ end as it is synthesised – to bring mRNA therapies to market faster.

Contrasting with other techniques, CleanCap® enables synthesis of cap-1 mRNA in a single step. In doing so, it can cut mRNA therapeutic production processes by almost a week and reduce overall manufacturing costs by as much as 40% compared to other capping methods. “Co-transcriptional caps can really simplify how you can set up synthesis reactions,” explains Hannah Ellerbrock, Director of RNA sciences at TriLink. “It’s going to make your development requirements much more straightforward, and it’s typically easier to scale that up.”

Amid the rise of mRNA technology, the underpinning market for innovative materials and services is evolving all the time. Biomanufacturers can keep ahead of the curve by working with research teams that have experience in bringing breakthroughs to this market. TriLink Biotechnologies comprises mRNA experts – they have pioneered transformational CleanCap® technology and have been in the industry even before the mRNA boom gathered momentum. To find out more about how they could boost your biomanufacturing firm’s efficiency, download the whitepaper on this page.

Sign up for our daily news round-up!

Give your business an edge with our leading industry insights.